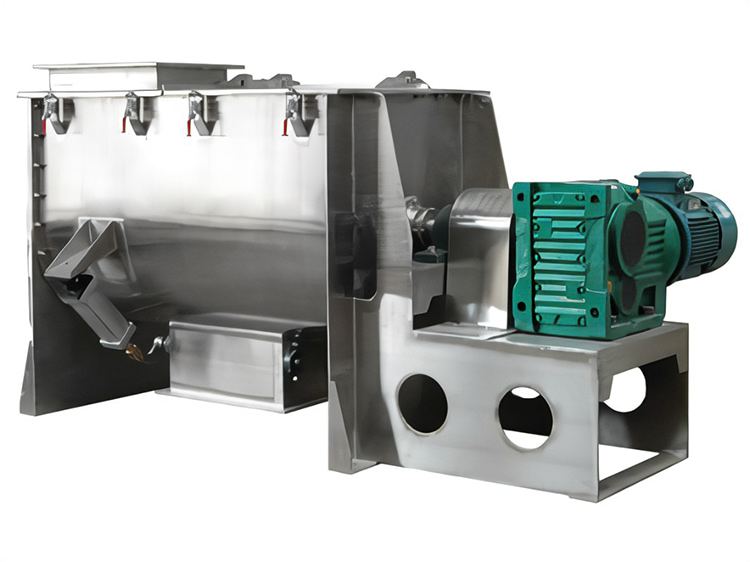

What Are the Advantages of Ribbon Mixer

A ribbon mixer, also called a ribbon blender, is one of the most widely used and versatile industrial mixing machines for powders, granules, and powder–liquid combinations. From plastics and chemicals to food ingredients and construction materials, manufacturers rely on ribbon mixers because they are efficient, cost-effective, and easy to maintain.

This guide explains the ribbon mixer working principle, the advantages of ribbon mixers, how to choose the right model, and why many companies prefer the Audop ribbon mixer for professional applications.

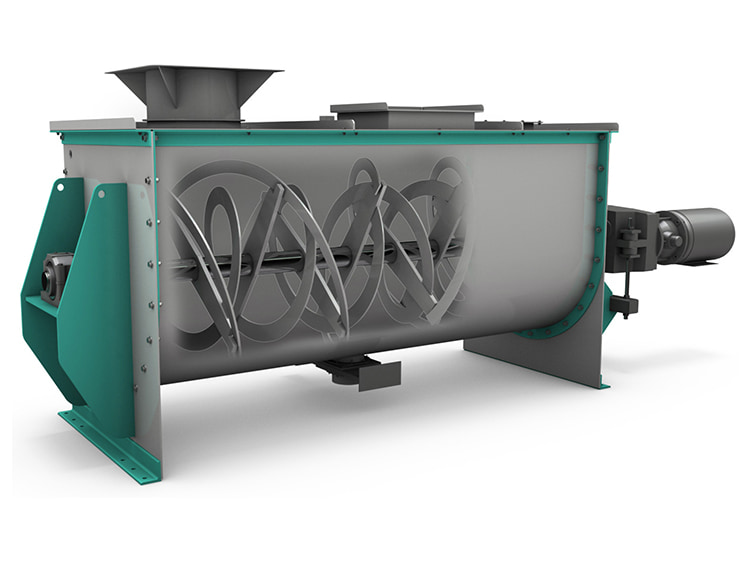

What Is a Ribbon Mixer?

A ribbon mixer is a horizontal mixing machine equipped with a rotating shaft and double-layer helical ribbons. These ribbons move materials in opposite directions-an action known for achieving fast and uniform blending.

Common Industries That Use Ribbon Mixers

Plastic additives and masterbatch

Chemical powders

Food powders and ingredients

Agricultural feed

Detergents and household products

Nutritional supplements

Building materials

If your process involves large-volume powder mixing, a ribbon mixer is often the most practical and efficient choice.

How Does a Ribbon Mixer Work?

The double-helix ribbons inside the mixing chamber move materials through two counterflow paths:

The outer ribbon pushes materials from the ends toward the center

The inner ribbon pushes materials from the center toward the ends

This creates a continuous folding and circulating motion that ensures every particle is exchanged.

Because of this design, ribbon mixers excel at:

Consistent powder blending

Fast mixing cycles

Handling formulas with small percentages of additives

Uniform coating in powder–liquid mixing

This working principle is one reason the ribbon mixer is considered one of the best mixers for industrial powder processing.

Advantages of Ribbon Mixer

1. High Mixing Efficiency

Ribbon mixers typically achieve uniformity in 5–15 minutes, making them ideal for high-volume production lines that require quick batch turnover.

2. Gentle Yet Effective Blending

Unlike high-shear mixers, ribbon mixers protect fragile particles such as granules, flakes, or heat-sensitive materials.

3. Large Range of Applications

A major reason for their popularity is versatility. Ribbon mixers can handle:

Free-flowing powders

Sticky powders (with coatings)

Fibrous materials

Powders with small liquid additions

Multi-density formulations

4. Easy Operation & Low Maintenance Cost

Operators appreciate the simple structure, straightforward controls, and easy-to-clean interiors-an important factor for industries requiring frequent material changes.

5. Excellent Cost–Performance Ratio

A ribbon mixer often provides the best value compared to other systems such as V-blenders, plow mixers, or twin-screw mixers.

How to Choose a Ribbon Mixer (Buyer's Guide)

Choosing the right industrial ribbon mixer depends on several technical and practical factors.

1. Capacity and Batch Volume

Optimal fill level is 40–70% of the total tank volume. This ensures enough space for proper movement and circulation.

2. Material Properties

Consider:

Bulk density

Particle size

Flowability

Moisture content

Fragility

This affects the ribbon design and shaft speed needed for ideal results.

3. Mixing Purpose

Your application determines the required configuration:

Powder–powder blending

Powder–liquid spraying

Coating or moistening

Light granule mixing

4. Mixer Construction Material

Choose based on safety and durability:

Carbon steel

Stainless steel 304

Stainless steel 316L

Polished food-grade surfaces

5. Custom Features

You may need:

Heating/cooling jackets

Spray nozzles

Vacuum mixing

Wear-resistant coatings

Automatic feeding and discharging systems

6. After-Sales Support and Reliability

Stable performance and long-term service matter just as much as the machine itself.

Why Choose Audop Ribbon Mixer?

Audop is known for reliable engineering and durable construction in industrial mixing equipment. The Audop ribbon mixer is designed to deliver precise mixing performance and long service life.

Key Strengths of Audop Ribbon Mixer

Optimized ribbon structure for fast, uniform blending;

Heavy-duty build suitable for abrasive or dense materials;

Customizable with spray systems, jackets, and automation;

Easy to clean and maintain;

Proven stability for long-term continuous operation.

For manufacturers comparing brands or searching for a dependable machine, the Audop ribbon mixer offers outstanding value, durability, and mixing consistency.

Ribbon Mixer FAQ

1. What materials can a ribbon mixer handle?

Powders, granules, fiber-like materials, and powder–liquid combinations.

2. How long does mixing take?

Typically 5–15 minutes, depending on material differences.

3. Does a ribbon mixer work for sticky materials?

Yes-lightly sticky powders work well. For very sticky materials, special coatings or alternative mixers may be required.

4. Can a ribbon mixer add liquid during mixing?

Yes. Many models support spray systems for coating or moistening powders.

5. Is a ribbon mixer easy to clean?

Yes. The open design and smooth interior surfaces allow quick cleaning.

6. Should I choose a jacketed ribbon mixer?

Yes if your process requires heating, cooling, or drying functions.

Final Thoughts

The ribbon mixer remains one of the most effective and cost-efficient machines for industrial powder mixing, granule blending, and powder–liquid processing. With fast mixing cycles, versatility, and simple maintenance, it's a reliable solution for a wide range of industries.

If you're searching for a durable, high-performance option, the Audop ribbon mixer stands out as a strong, professional choice.

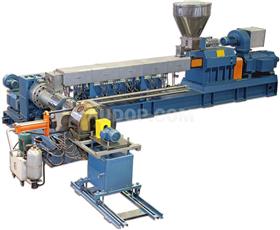

Emerging Trends Shaping Plastic Extruders in 2026

Plastic Extruders in 2026 feature smart manufacturing,AI,and sustainable materials,boosting efficiency,quality,and market growth.

China Professional Two-Stage Twin Screw & Single Screw Compounding Extruder Manufacturer-Audop

Audop is a leading China manufacturer of two-stage twin screw and single screw compounding extruders,offering high-efficiency,stable,and customized solutions for plastic modification,masterbatch,PVC,WPC,biodegradable and recycled materials.

The Extruder of HDPE Pipe Production Line

Discover how the extruder plays a vital role in the HDPE pipe production line.Learn how the Audop HDPE Pipe Extrusion Line ensures high-quality melting,precision shaping,and energy-efficient operation for durable HDPE pipes.

PET Bottle Hot Washing Recycling Machine Technology Flow Guide

Discover how a PET Bottle Hot Washing Recycling Machine transforms dirty PET bottles into high-purity recycled flakes.Learn the full technology flow,including sorting,crushing,hot washing,separation,and drying for efficient and high-quality PET recycling.

Plastic Crusher: Recycling and Manufacturing Solution

Boost your recycling efficiency with the Audop Plastic Crusher.Learn how this durable,high-performance machine transforms plastic waste into reusable material for sustainable manufacturing.